DOI:

https://doi.org/10.64539/msts.v1i2.2025.342Keywords:

Thin Film Deposition, ZnO, Techniques, Challenges, ProspectsAbstract

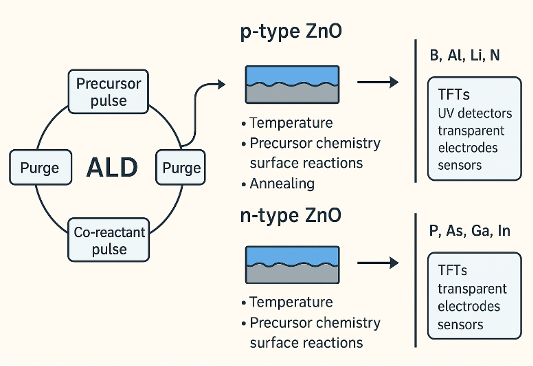

This research dives into the field of thin film deposition, with a particular emphasis on its application in ZnO-based semiconductors. The examination tries to illustrate the array of benefits, intricate challenges, and bright prospects inherent in this field through an in-depth case study. Notably, the work emphasizes the benefits of thin film deposition techniques in ZnO-based semiconductor production, such as precise control over film thickness, improved material use, and the ability to modify electrical properties. It does, how-ever, recognize the difficulties in assuring uniformity and quality control in deposition, dealing with complex deposition processes, addressing interface effects to maximize device performance, and navigating material compatibility constraints. In terms of the future, the study sees significant potential in the development of advanced materials to augment ZnO-based semiconductor functionalities, the incorporation of nanotechnology to boost performance, and the emergence of novel monitoring strategies for real-time quality assurance during deposition. Sustainable deposition methods are also being considered considering environmental concerns. The study continues by emphasizing the revolutionary significance of ZnO-based semiconductors in many applications and emphasizing the importance of interdisciplinary collaboration to unlock the full spectrum of benefits and overcome hurdles in this dynamic field. This research provides a comprehensive look at the complex domain of thin film deposition in ZnO-based semiconductor environments, shedding light on its potential to transform technological landscapes and inspire creative solutions.

References

[1] T. Suemasu and D. B. Migas, “Recent Progress Toward Realization of High‐Efficiency BaSi2 Solar Cells: Thin‐Film Deposition Techniques and Passivation of Defects,” physica status solidi (a), vol. 219, no. 1, Jan. 2022, https://doi.org/10.1002/pssa.202100593.

[2] A. Jolivet et al., “Structural, optical, and electrical properties of TiO2 thin films deposited by ALD: Impact of the substrate, the deposited thickness and the deposition temperature,” Appl Surf Sci, vol. 608, p. 155214, Jan. 2023, https://doi.org/10.1016/j.apsusc.2022.155214.

[3] D. Muñoz-Rojas, T. Maindron, A. Esteve, F. Piallat, J. C. S. Kools, and J.-M. Decams, “Speeding up the unique assets of atomic layer deposition,” Mater Today Chem, vol. 12, pp. 96–120, Jun. 2019, https://doi.org/10.1016/j.mtchem.2018.11.013.

[4] B. Gupta et al., “Recent Advances in Materials Design Using Atomic Layer Deposition for Energy Applications,” Adv Funct Mater, vol. 32, no. 3, Jan. 2022, https://doi.org/10.1002/adfm.202109105.

[5] J. Colin et al., “In Situ and Real-Time Nanoscale Monitoring of Ultra-Thin Metal Film Growth Using Optical and Electrical Diagnostic Tools,” Nanomaterials, vol. 10, no. 11, p. 2225, Nov. 2020, https://doi.org/10.3390/nano10112225.

[6] T. J. Z. Stock et al., “Atomic-Scale Patterning of Arsenic in Silicon by Scanning Tunneling Microscopy,” ACS Nano, vol. 14, no. 3, pp. 3316–3327, Mar. 2020, https://doi.org/10.1021/acsnano.9b08943.

[7] N. Tiwari, A. Nirmal, M. R. Kulkarni, R. A. John, and N. Mathews, “Enabling high performance n-type metal oxide semiconductors at low temperatures for thin film transistors,” Inorg Chem Front, vol. 7, no. 9, pp. 1822–1844, 2020, https://doi.org/10.1039/D0QI00038H.

[8] Z. Wang, Z. Chen, J. Wang, L. Shangguan, S. Fan, and Y. Duan, “Realization of an autonomously controllable process for atomic layer deposition and its encapsulation application in flexible organic light-emitting diodes,” Opt Express, vol. 31, no. 13, p. 21672, Jun. 2023, https://doi.org/10.1364/OE.488152.

[9] A. Pulici et al., “Electrical characterization of thin silicon-on-insulator films doped by means of phosphorus end-terminated polymers,” Mater Sci Semicond Process, vol. 163, p. 107548, Aug. 2023, https://doi.org/10.1016/j.mssp.2023.107548.

[10] S. Vallinayagam, S. N. Nisha, R. S. Nandhini, A. S. Babu, J. Palanivelu, and S. Gayathri, “Atomic Layer Deposition (ALD) Utilities in Bioenergy Conversion and Energy Storage,” in Materials for Sustainable Energy Storage at the Nanoscale, Boca Raton: CRC Press, 2023, pp. 51–65. https://doi.org/10.1201/9781003355755-4.

[11] V. Chauhan, G. Vashisht, D. Gupta, S. Kumar, and R. Kumar, “Atomic layer deposition of ferrite thin films,” in Ferrite Nanostructured Magnetic Materials, Elsevier, 2023, pp. 267–292. https://doi.org/10.1016/B978-0-12-823717-5.00050-4.

[12] J. Jiang, R. Zhang, and W. Wu, “Wearable Sensors Based on Atomically Thin P‐Type Semiconductors,” Adv Mater Technol, vol. 8, no. 18, Sep. 2023, https://doi.org/10.1002/admt.202300517.

[13] B. K. Yap, Z. Zhang, G. S. H. Thien, K.-Y. Chan, and C. Y. Tan, “Recent advances of In2O3-based thin-film transistors: A review,” Applied Surface Science Advances, vol. 16, p. 100423, Aug. 2023, https://doi.org/10.1016/j.apsadv.2023.100423.

[14] C. T. Nguyen et al., “Area-Selective Deposition of Ruthenium Using Homometallic Precursor Inhibitor,” Chemistry of Materials, vol. 35, no. 14, pp. 5331–5340, Jul. 2023, https://doi.org/10.1021/acs.chemmater.3c00525.

[15] M. R. Zaman, S. Sarker, M. A. Halim, S. Ibrahim, and A. Haque, “A Thorough Analysis of the Opportunities and Challenges of Community Microgrid System Based on Renewable Energy in Bangladesh,” Control Systems and Optimization Letters, vol. 2, no. 1, pp. 28–35, Feb. 2024, https://doi.org/10.59247/csol.v2i1.71.

[16] H. Guan, B. Zhao, W. Zhao, and Z. Ni, “Liquid-precursor-intermediated synthesis of atomically thin transition metal dichalcogenides,” Mater Horiz, vol. 10, no. 4, pp. 1105–1120, 2023, https://doi.org/10.1039/D2MH01207C.

[17] J. Li, G. Chai, and X. Wang, “Atomic layer deposition of thin films: from a chemistry perspective,” International Journal of Extreme Manufacturing, vol. 5, no. 3, p. 032003, Sep. 2023, https://doi.org/10.1088/2631-7990/acd88e.

[18] A. Weiß et al., “Conversion of ALD CuO Thin Films into Transparent Conductive p‐Type CuI Thin Films,” Adv Mater Interfaces, vol. 10, no. 3, Jan. 2023, https://doi.org/10.1002/admi.202201860.

[19] M. Abdelfatah et al., “Inverting electrodeposited nanostructured Cu2O thin films from n-type to p-type semiconductors and variation of their physical and photoelectrochemical properties for optoelectronic applications,” Ceram Int, vol. 49, no. 18, pp. 30732–30743, Sep. 2023, https://doi.org/10.1016/j.ceramint.2023.07.029.

[20] D. E. Gomersall et al., “Multi-pulse atomic layer deposition of p-type SnO thin films: growth processes and the effect on TFT performance,” J Mater Chem C Mater, vol. 11, no. 17, pp. 5740–5749, 2023, https://doi.org/10.1039/D3TC00255A.

[21] W. Ehrmann, The Evolution of Consciousness: Seven Steps of Integral Healing. tredition, 2023. [Online]. Available: https://www.amazon.com/Evolution-Consciousness-Seven-Integral-Healing-ebook/dp/B0DSL6TFRX.

[22] C. Kim et al., “Atomic Layer Deposition Route to Scalable, Electronic-Grade van der Waals Te Thin Films,” ACS Nano, vol. 17, no. 16, pp. 15776–15786, Aug. 2023, https://doi.org/10.1021/acsnano.3c03559.

[23] S. Stefanovic et al., “Direct‐Patterning ZnO Deposition by Atomic‐Layer Additive Manufacturing Using a Safe and Economical Precursor,” Small, vol. 19, no. 36, Sep. 2023, https://doi.org/10.1002/smll.202301774.

[24] E. S. Kessler-Lewis et al., “Development of MOVPE grown GaSb-on-GaAs interfacial misfit solar cells,” J Appl Phys, vol. 133, no. 24, Jun. 2023, https://doi.org/10.1063/5.0141163.

[25] E. Coleman et al., “Scrutinizing pre- and post-device fabrication properties of atomic layer deposition WS2 thin films,” Appl Phys Lett, vol. 123, no. 1, Jul. 2023, https://doi.org/10.1063/5.0151592.

[26] J. Kim et al., “High-performance Atomic-Layer-Deposited SnO thin film transistors fabricated by intense pulsed light annealing,” Appl Surf Sci, vol. 609, p. 155281, Jan. 2023, https://doi.org/10.1016/j.apsusc.2022.155281.

[27] A. F. M. A. U. Bhuiyan, Z. Feng, L. Meng, and H. Zhao, “Tutorial: Metalorganic chemical vapor deposition of β-Ga2O3 thin films, alloys, and heterostructures,” J Appl Phys, vol. 133, no. 21, Jun. 2023, https://doi.org/10.1063/5.0147787.

[28] A. Haque, Md. N. Hussain, Md. S. Ali, Md. Y. A. Khan, and M. A. Halim, “Technical and Economic Challenges and Future Prospects of a Smart Grid - A Case Study,” Control Systems and Optimization Letters, vol. 1, no. 3, pp. 186–193, Jan. 2024, https://doi.org/10.59247/csol.v1i3.57.

[29] J. Wang et al., “Field effect transistor‐based tactile sensors: From sensor configurations to advanced applications,” InfoMat, vol. 5, no. 1, Jan. 2023, https://doi.org/10.1002/inf2.12376.

[30] Z. Lin, Z. Wang, J. Zhao, X. Li, and M. Si, “A Low-Leakage Zinc Oxide Transistor by Atomic Layer Deposition,” IEEE Electron Device Letters, vol. 44, no. 3, pp. 536–539, Mar. 2023, https://doi.org/10.1109/LED.2022.3233943.

[31] Z. Starowicz et al., “Synthesis and characterization of Al-doped ZnO and Al/F co-doped ZnO thin films prepared by atomic layer deposition,” Materials Science and Engineering: B, vol. 292, p. 116405, Jun. 2023, https://doi.org/10.1016/j.mseb.2023.116405.

[32] E. G. Dyrvik et al., “Reducing Nonradiative Losses in Perovskite LEDs through Atomic Layer Deposition of Al 2 O 3 on the Hole-Injection Contact,” ACS Nano, vol. 17, no. 4, pp. 3289–3300, Feb. 2023, https://doi.org/10.1021/acsnano.2c04786.

[33] A. K. Patwary, M. A. Sayem, M. A. Hossain, and Md. A. Halim, “A Review of Energy Storage Systems (ESS) for Integrating Renewable Energies in Microgrids,” Control Systems and Optimization Letters, vol. 2, no. 1, pp. 103–112, Apr. 2024, https://doi.org/10.59247/csol.v2i1.68.